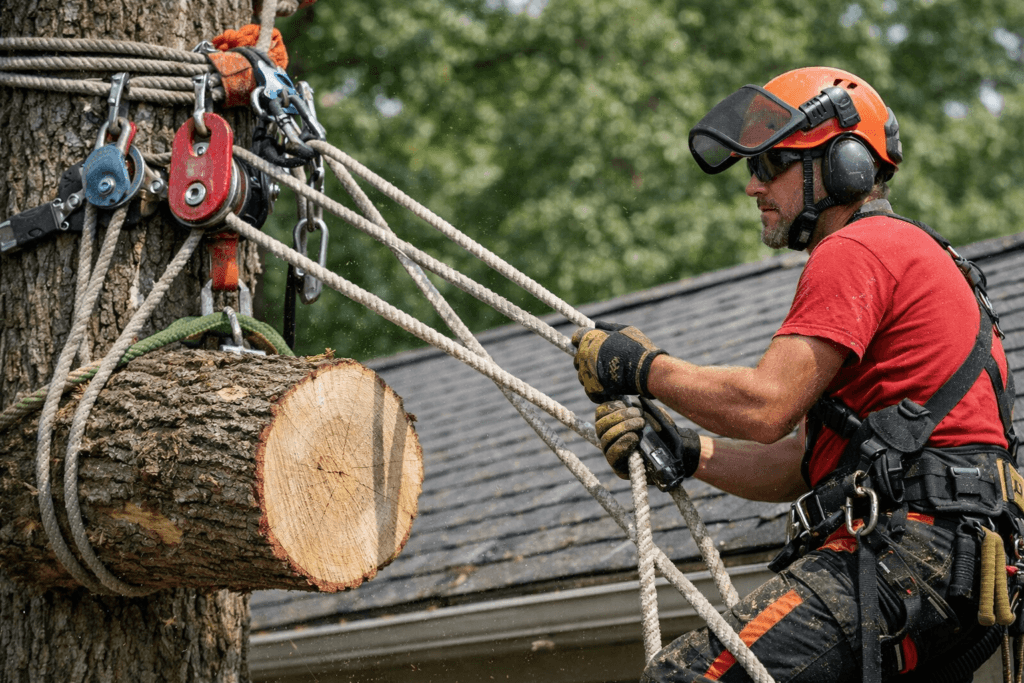

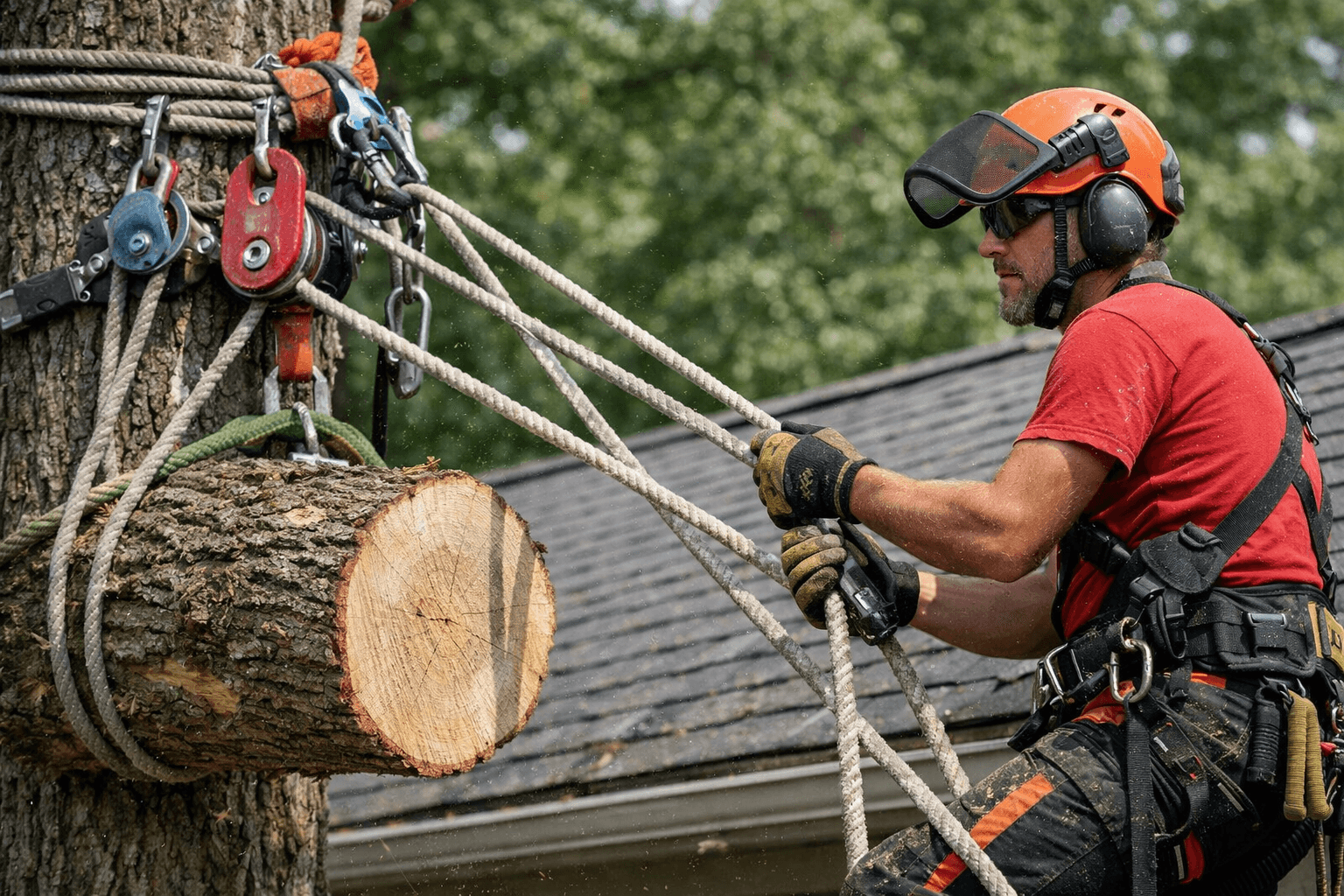

I’ve spent 15 years in a saddle, and if there’s one thing I’ve learned, it’s that gravity doesn’t negotiate. In 2026, we aren’t just “cutting trees”; we are managing massive dynamic loads in tight residential spaces. If you’re still relying on brute force instead of mechanical advantage in tree rigging, you’re an accident waiting to happen. When you’re staring down a 4,000-pound section of white oak hanging over a million-dollar roof, you need more than just a sharp saw—you need physics. That’s where the 5:1 system comes in.

Table of Contents

Why 5:1 Mechanical Advantage is the Gold Standard in 2026

In my early years, we’d just “man-handle” pieces. Today, OSHA 1910.266 and ANSI Z133 standards are much stricter about load control. A 5:1 mechanical advantage system essentially allows you to pull 500 pounds of weight using only 100 pounds of force. For a technical arborist, this isn’t just about making work “easier”—it’s about precision. When you’re performing a technical tree removal on a compromised stem, the last thing you want is a sudden shock load shattering the trunk.

The Technical Setup: Pulleys, Friction, and Force

To master mechanical advantage in tree rigging, you have to understand the hardware. We’ve moved past basic blocks. In 2026, the gear is more efficient, but the physics remains the same.

- The Hardware: I exclusively use ISC Impact Blocks and high-efficiency triple-action pulleys.

- Friction Management: Every bit of friction in a cheap pulley eats into your mechanical advantage in tree rigging.

- The Rope: High-modulus, low-stretch rigging lines are mandatory to ensure the 5:1 system doesn’t lose energy to “rope stretch”.

- The Anchor: Whether it’s a basal anchor or a redirected high-point, your anchor must be rated for at least double the expected dynamic load.

Directional Felling and Dismantling with MA

When dismantling a tree in sections, mechanical advantage in tree rigging allows you to “pre-tension” a limb. This prevents the limb from dropping even an inch when the cut is completed.

- The Notch: Use a 70-degree open-face notch for maximum control.

- The Pull: Use your 5:1 system to put just enough “lean” on the piece to counteract gravity.

- The Release: As the hinge folds, the mechanical advantage in tree rigging steers the log into the “drop zone” with surgical accuracy.

OSHA Safety and ISA Protocols

If you aren’t following ISA (International Society of Arboriculture) protocols, you shouldn’t be in the air.

- Voice Commands: In 2026, clear comms like the Protos Integral are a safety requirement to coordinate the pull.

- Shock Loading: Never ignore the “G-Factor.” A piece that weighs 500 lbs can exert 5,000 lbs of force if dropped into a static line.

- Risk Assessment: Always perform a Level 3 Risk Assessment before applying mechanical advantage in tree rigging on a dead or “zombie” tree.

The Reality of the Job: Why MA Wins

Look, I’ve seen guys snap 3/4-inch Bull Rope because they didn’t understand mechanical advantage in tree rigging. They thought they could out-muscle the timber. You can’t. Every dismantle is a math problem. If you solve it wrong, someone goes to the hospital. Solve it right using a 5:1 system, and you go home with a paycheck and a clean conscience. Using mechanical advantage in tree rigging is what separates the professionals from the amateurs in the 2026 arboriculture industry.

2 thoughts on “Mastering 5:1 Mechanical Advantage: A Technical Guide to Heavy Timber Rigging (2026)”