In the world of professional arboriculture, the difference between a successful job and a catastrophic accident usually comes down to one thing: how strictly you follow safety standards. After 15 years in the saddle, I’ve learned that the canopy is no place for ego or shortcuts. Whether you are a homeowner or a rookie climber, understanding professional safety standards is the only way to ensure you go home at the end of the day.

In 2026, with higher temperatures and unpredictable storm patterns, the structural integrity of trees is changing, making these safety standards more critical than ever before.

1. OSHA 1910.266: The Law of the Canopy

In the United States, our primary safety standards are dictated by OSHA. Specifically, the 1910.266 standard for logging and tree care operations. This isn’t just paperwork; it’s a set of blood-bought rules.

- PPE (Personal Protective Equipment): Following safety standards means never starting a saw without chainsaw chaps, a rated helmet, and eye protection.

- The Drop Zone: You must establish a clear work area that is twice the height of the tree.

- Communication: Modern safety standards now recommend Bluetooth-enabled helmets to maintain clear contact between the climber and the ground crew.

2. ISA Protocols and the “Tie-In-Twice” Rule

While OSHA is the law, the International Society of Arboriculture (ISA) provides the technical safety standards for climbing.

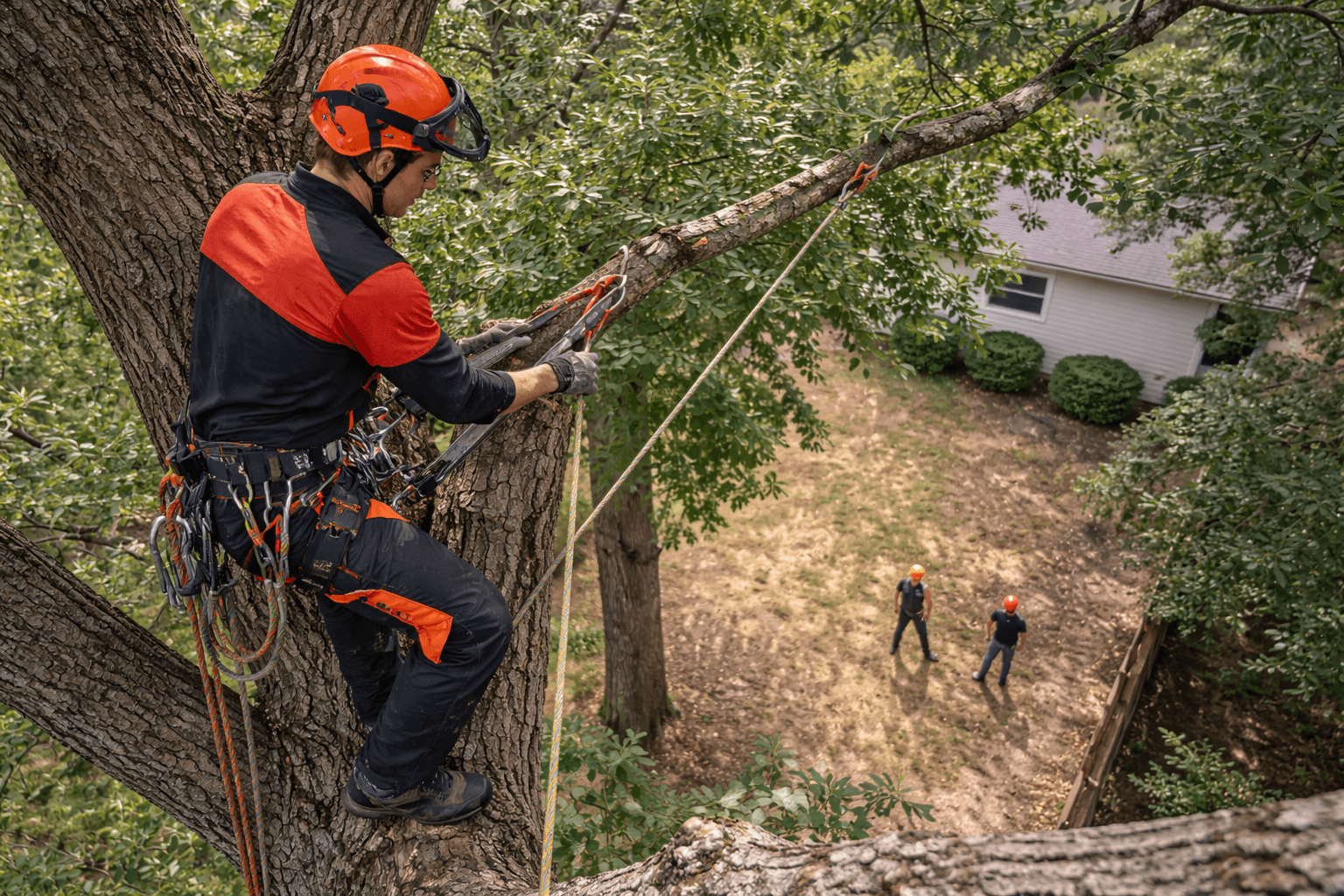

- Redundancy: One of the most vital safety standards is the “Two-Point Tie-In.” If you are using a chainsaw in the tree, you must be secured by two independent anchor points.

- Anchor Inspection: Before putting your weight on a line, safety standards require you to test your anchor point with a “pull test” twice the weight of the climber.

3. Technical Rigging and Load Standards

Rigging is where physics meets forestry. If you don’t follow rigging-specific safety standards, you risk property damage or worse.

- Mechanical Advantage: We use 5:1 systems to manage heavy timber, but these systems only work if you respect the load limits of your hardware.

- Friction Management: Professional safety standards mandate the use of Port-a-Wraps or friction bollards to ensure the ground crew has full control over falling limbs.

4. Why Alex Tree Climber Prioritizes These Standards

My mission with this site is to make these high-level safety standards accessible to everyone. When I’m using SRT (Stationary Rope Technique) to access a 100-foot canopy, I’m relying on the gear and the protocols I’ve mastered over 15 years.

Ignoring safety standards might save you ten minutes, but it could cost you a lifetime. If a job looks too dangerous or if you don’t have the right load-rated gear, the best of all safety standards is to stop the work and call in a professional crew.

1 thought on “Professional Tree Work Safety Standards: The 2026 Guide to OSHA & ISA Compliance”