Table of Contents

1. The Brutal Reality of Dead Oak Removal Rigging

I was on a job once—big dead red oak, backyard removal, tight drop zone. Homeowner breathing down our necks. Looked solid from the ground. From the saddle? Thing felt like cork. I set a block, pre-tensioned the line, made my cut… and the top didn’t swing

It exploded.

Fiber shear. No hinge. Rigging line screamed like a banshee. You know that sound when the line hums under tension and your stomach drops? Yeah. That sound.

That was the day I stopped treating dead oak removal rigging like normal rigging.

If you climb long enough, dead oaks will test you. Not your strength—your judgment.

The Problem: Treating Dead Oak Like It’s Still Alive

Here’s the mistake I see over and over:

Climbers rig dead oak the same way they rig green wood.

That’s how people get hurt.

Dead oak doesn’t bend.

Dead oak doesn’t talk before it fails.

Dead oak doesn’t give you a hinge—you get a barber-chair, a snap, or nothing at all.

Common screw-ups:

- Trusting hinge wood that’s already punky

- Negative rigging without reducing load

- Anchoring into compromised spar wood

- Assuming weight instead of testing density

Check-in: Ever cut into a dead oak and had your saw suddenly drop because the wood just vanished? That’s your warning sign. Miss it, and the tree decides for you.

Why Dead Oak Removal Rigging Is High-Stakes Work

Oak fails different. Especially red oak.

You’re dealing with:

- Brittle fiber structure

- Hidden rot pockets

- Unpredictable shear planes

- Delayed failure (the piece holds… then goes)

Dead oak loves making liars out of confident climbers.

That’s why dead oak removal rigging deserves its own rules.

The Safety Audit: What OSHA & ANSI Z133 Actually Expect

I’m not here to quote manuals like a safety officer—but if something goes wrong, this is what they’ll measure you against.

OSHA basics that matter here:

- You are required to evaluate structural integrity before climbing.

- You must identify decay, dead wood, and hazards before cutting.

- You must use proper rigging rated for expected loads (not guessed loads).

ANSI Z133 gets more specific:

- Dead or compromised trees require alternative access methods if unsafe.

- Rigging points must be sound and verified, not assumed.

- Cutting techniques must account for wood condition, not just size.

Translation in real-world terms?

If you rig dead oak like green oak and it fails, that’s on you.

The Solution: Dead Oak Removal Rigging Done the Hard Way (The Right Way)

Step 1: Prove the Tree Is Climbable

Before rope ever leaves the bag:

- Sound the trunk with a mallet

- Bore test critical sections

- Check for seam cracks and shell thickness

- Look for fungal bodies at unions

If you can’t prove it’s solid—don’t climb it. Bucket. Crane. Or walk.

Pride doesn’t pay hospital bills.

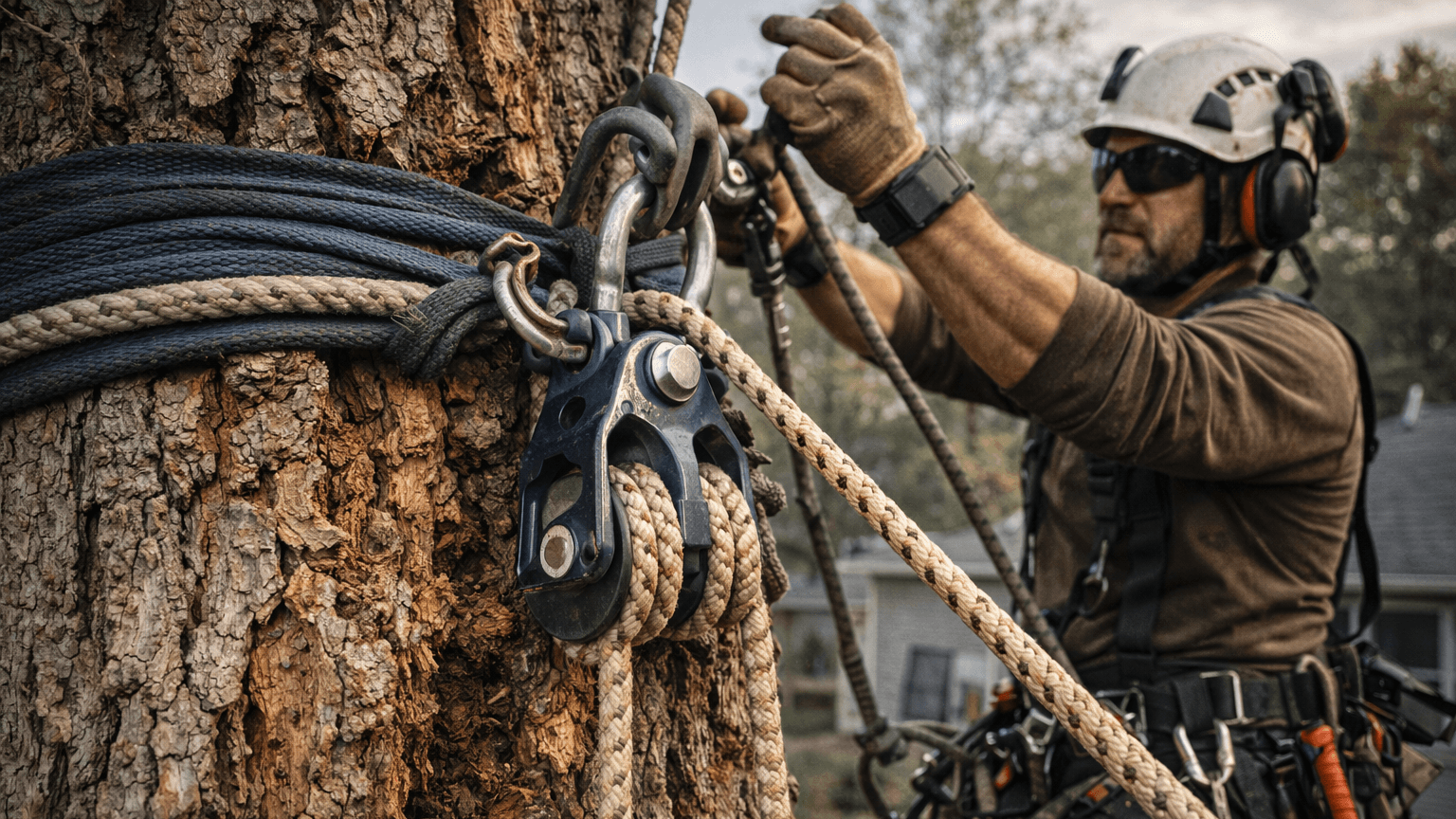

Step 2: Overbuild the Rigging (Then Overbuild It Again)

Dead oak gets zero forgiveness.

Rules I follow:

- Higher-rated rope than normal

- Blocks instead of natural crotches

- Backup anchor when possible

- No shock loading. Ever.

If you’re wondering whether your rigging is enough—it’s not.

Step 3: Cut Size Is Your First Safety Device

Dead oak pieces should be:

- Smaller than you think

- Lighter than you planned

- Balanced before release

Forget efficiency. You’re buying control.

Ask yourself:

If this piece free-fell three feet, would the system survive?

If the answer isn’t a calm “yes,” cut it smaller.

Step 4: Rig for Vertical, Not Swing

Swing loads kill systems in dead oak.

Best options:

- Straight down rigging

- Speedline only if anchors are bombproof

- Controlled negative rigging with hard pretension

Avoid:

- Big lateral swings

- Dynamic catches

- One-point anchors in suspect wood

Dead oak doesn’t absorb energy—it transfers it.

Step 5: Your Cut Matters More Than Ever

Forget pretty hinges.

What works better:

- Holding wood straps

- Step cuts with controlled release

- Pre-cut relief kerfs to manage fiber tear

Never rely on:

- Standard face cuts

- Snap cuts in brittle wood

- Thin hinge assumptions

Dead oak doesn’t hinge—it fails.

Dead Oak Removal Rigging: The Mental Game

Here’s the part nobody talks about.

Dead oak messes with your head.

You rush because:

- The tree looks easy

- The homeowner is watching

- You’ve “done worse before”

That’s when it bites.

Check-in: Ever felt that urge to “just take one more piece” instead of resetting? That’s how near-misses are born.

Slow is smooth. Smooth keeps you climbing another year.

Common Failure Scenarios (And How to Avoid Them)

- Hanger breaks loose unexpectedly

→ Always assume dead hangers are loaded springs - Barber-chair at the union

→ Reduce piece size and pre-relieve fibers - Anchor point fails mid-lower

→ Verify wood integrity above AND below - Rigging line shock loads

→ Pretension and reduce drop distance

If you’ve seen one of these, you already know—dead oak teaches fast and hard.

Information Card: Dead Oak Removal Rigging Reference

| Factor | Green Oak | Dead Oak |

|---|---|---|

| Fiber Flex | High | Near zero |

| Hinge Reliability | Predictable | Unreliable |

| Anchor Strength | Assumed | Must be proven |

| Cut Size | Medium | Small |

| Rigging Margin | Standard | Overbuilt |

| Failure Style | Gradual | Sudden |

Tape this to your brain.

Final Word From a Guy Who’s Still Climbing

Dead oak removal rigging isn’t about being brave.

It’s about being honest.

Honest about:

- The wood

- The load

- Your system

- Your limits

I’ve buried friends in this trade. Not from lack of skill—but from treating dangerous trees like routine jobs.

If this post made you rethink even one cut, it did its job.

1 thought on “7 Brutal Truths About Dead Oak Removal Rigging That Keep Climbers Alive”