In the world of professional arboriculture, Complex Tree Removal is often described as “surgical dismantling”. When you are faced with a massive canopy hanging over a fragile roof or a tight garden space, there is zero room for error. After 15 years in the saddle, I can tell you that mastering Complex Tree Removal is all about understanding the physics of ropes, redirects, and friction management.

Table of Contents

Mastering Complex Tree Removal: 7 Essential Secrets of Ropes and Redirects

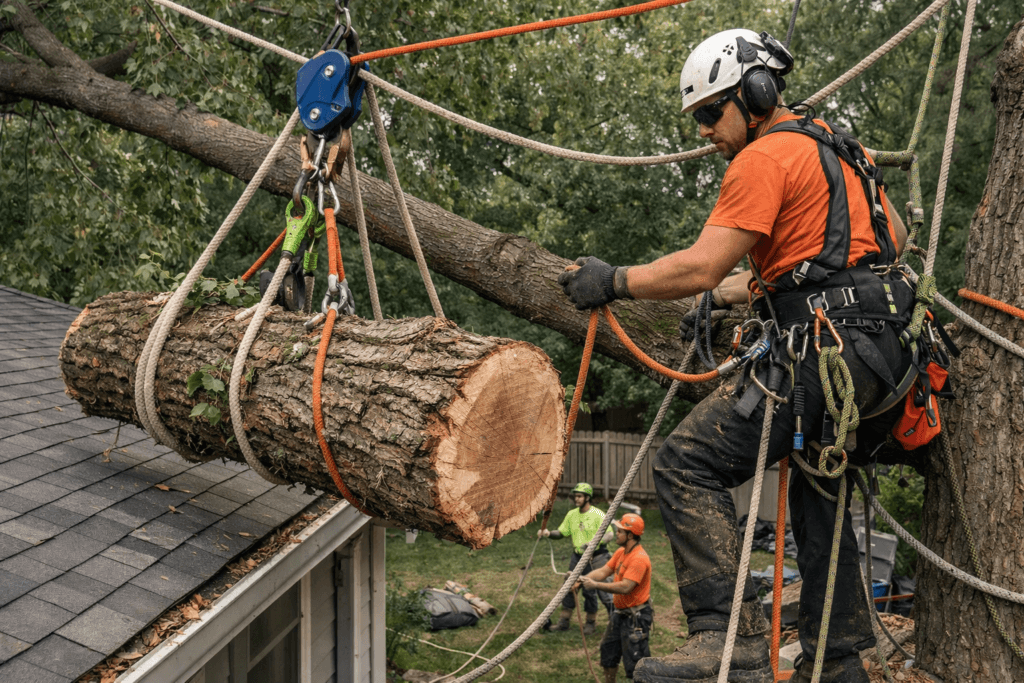

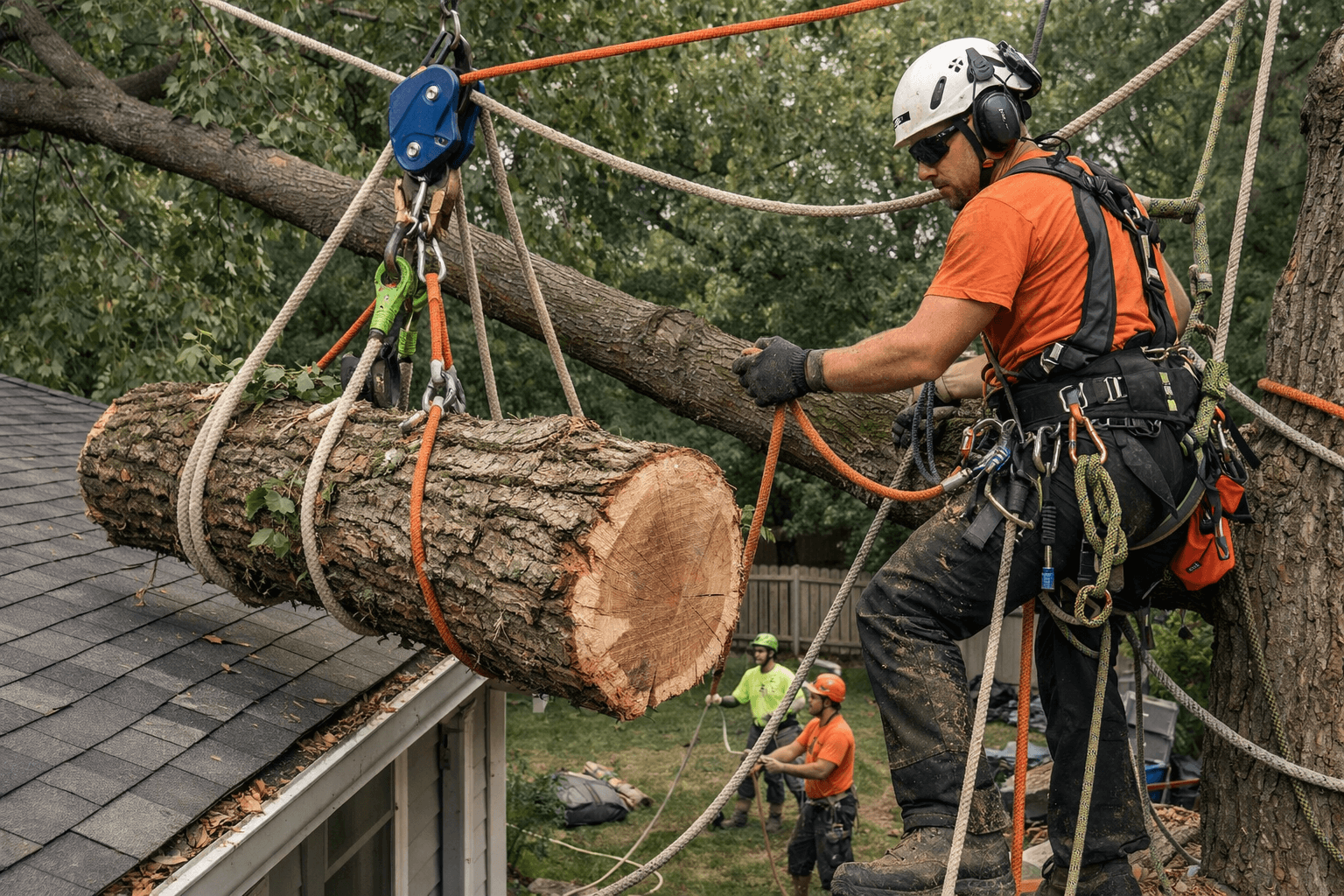

Complex Tree Removal is what we call “surgical dismantling” in the industry. When a 100-foot pine is leaning over a glass sunroom, there is zero room for error, and that is where the science of advanced rigging becomes your greatest asset. In these high-stakes scenarios, Complex Tree Removal requires a deep understanding of vector forces, friction management, and high-tensile rigging systems to ensure every limb hits the ground with soft precision.

1. The Power of Technical Redirects

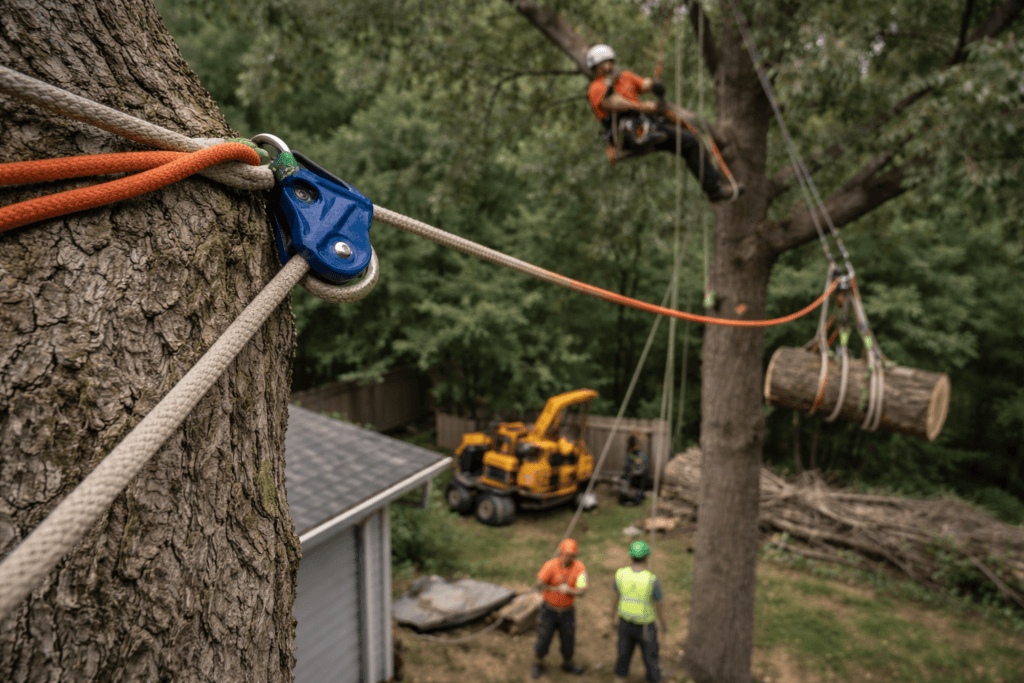

A redirect is a rigging configuration where the rope is passed through a block or pulley to change the angle of the pull.

- Leverage and Control: Redirects allow the ground crew to stand in a safe “no-drop zone” while still maintaining total control over the limb.

- Moving Around Obstacles: By placing a redirect pulley on a neighboring tree or a lower limb, we can pull a piece away from a house as it is being lowered.

- Force Management: Strategic redirects help distribute the kinetic energy across multiple points in the tree, reducing the stress on a single anchor.

2. Using Ropes for Sectional Dismantling

In Complex Tree Removal, we rarely drop a whole tree; we take it apart piece by piece.

- Primary Rigging Point: I establish a high anchor point using a specialized impact block that can handle the shock of falling wood.

- Bull Ropes: We use high-tensile, low-stretch bull ropes (usually 5/8″ or 3/4″) that are specifically designed for heavy lowering.

- Negative Rigging: This occurs when a limb is cut above the rigging point, causing it to fall into the rope. This requires a deep understanding of fall factors to prevent rope failure.

3. Friction Control and The Port-A-Wrap

The secret to safe Complex Tree Removal isn’t just holding the rope; it’s managing the friction.

- The Port-A-Wrap: This is a steel friction brake mounted at the base of the tree.

- Mechanical Advantage: It allows a single ground worker to lower a 1,000-pound log with just one hand by using “wraps” to create friction.

- Heat Dissipation: Professional friction devices are built to handle the heat generated by a sliding rope, preventing “rope burn” and melting.

4. OSHA Safety and Rigging Protocols

We follow OSHA 1910.266 and ANSI Z133 because they are written in the blood of workers who didn’t take rigging seriously.

- The Two-Point Rule: While rigging and cutting, I am always secured to the tree by at least two points of attachment for stability.

- Communication: In Complex Tree Removal, clear signals between the climber and the ground crew are mandatory, often using Bluetooth helmet radios.

- Equipment Inspection: Every rope and pulley is inspected for “glazing” or fiber breaks before every high-tension lift.

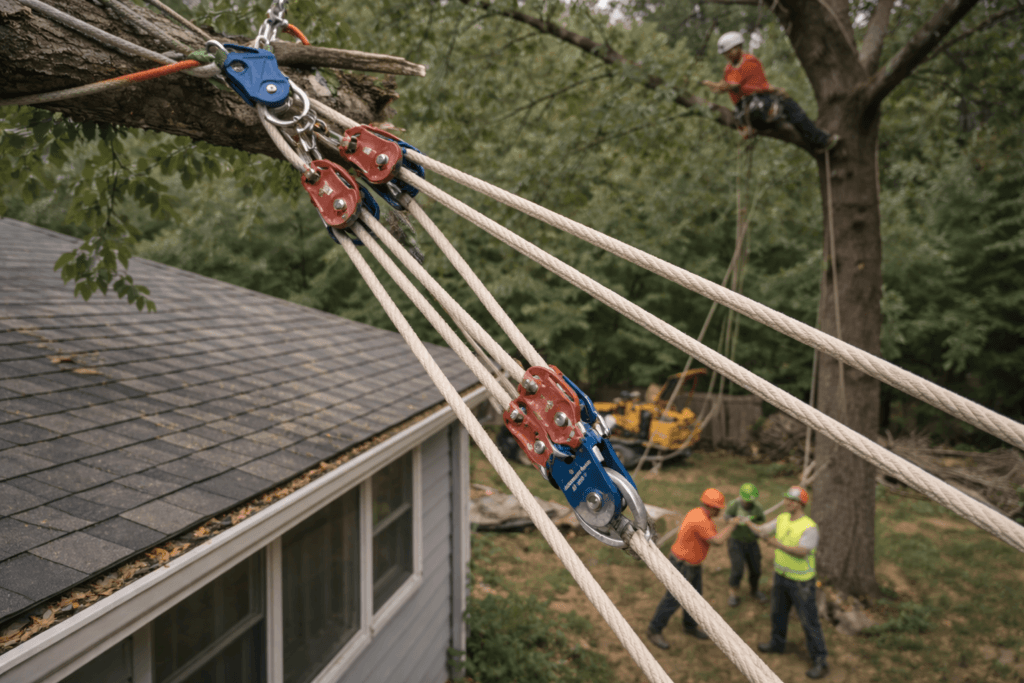

5. Lifting Systems (Mechanical Advantage)

Sometimes, a limb is “trapped” and cannot be lowered straight down.

- 5:1 Systems: We use pulleys to create a 5:1 mechanical advantage, allowing us to actually lift a heavy limb off a roof before swinging it clear.

- Dynamic Loading: We calculate the weight of the green wood (Oak is much heavier than Pine) to ensure our rigging system never hits its breaking strength.

1 thought on “5 Secret Complex Tree Removal Methods for Total Safety”